ENDWINDING MONITORING

Description

Current operating practices place severe thermal and mechanical stresses on the rotors and stators of large pump storage hydro and turbo generators.

These practices involve multiple daily run-ups and run-downs of the machines, which can lead to premature ageing and cycle-related deterioration of the stator windings.

Pump storage, hydro-generator and nuclear turbo-generator designs are characterized by extremely long end winding assemblies and complex spacer systems that are subject to high mechanical and electrical stresses and are predominantly excited by electromagnetic forces due to the interaction of a magnetic field and an electrical current.

Extending the service life of the generators and increasing their availability can only be achieved by continuous monitoring of the end winding structures and stator bars to detect any foreseeable deterioration of structural integrity.

Typical faults detections

- Loosening of endwinding support

- Wear of insulation

- Rupture of coil

- Fatigue cracking of conductors

- Rotor unbalance

- Alternating air-gap torque

Typical installation

Depending on the generator size, between 6 to 9 sensors installed uniformly around the endwinding in the radial direction on each side. Bump test is recommended to identify the best sensors location.

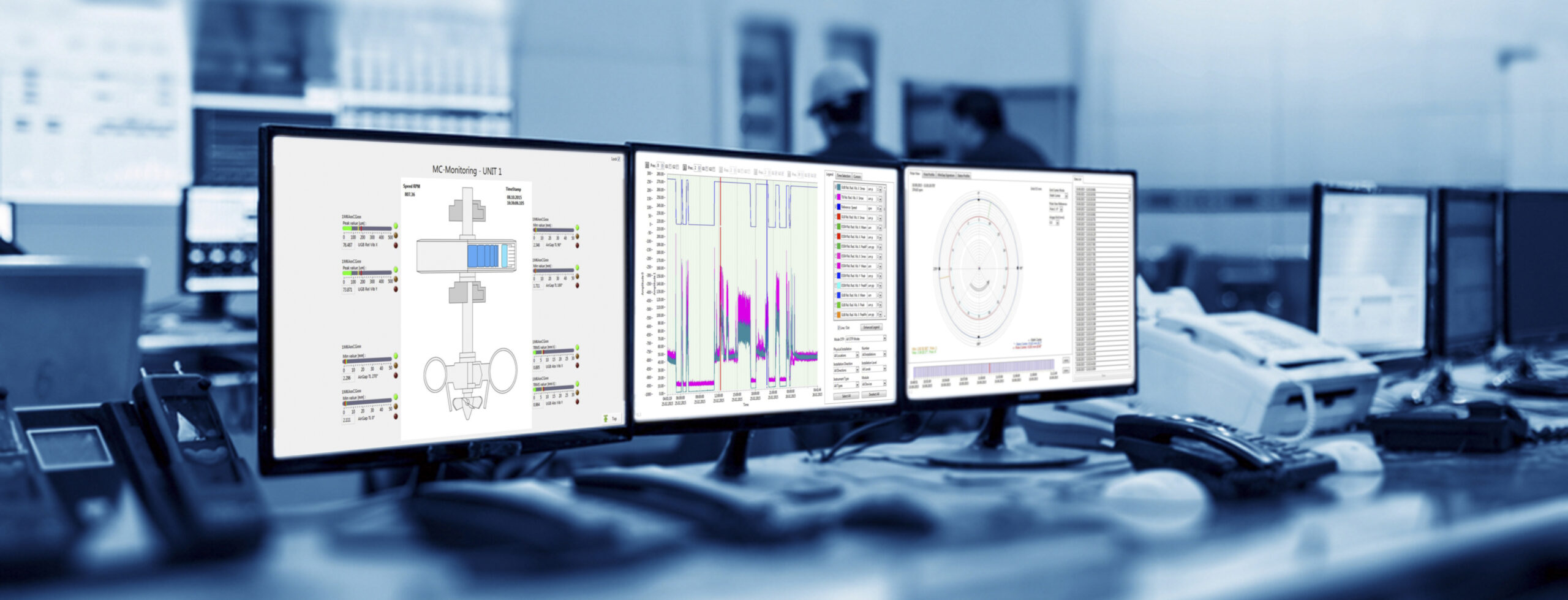

Monitoring parameters

- MPS: Vibration amplitude @ 2X of the network frequency

- CMS: Trending of vibration amplitude: broadband, 1X and 2X of the network frequency

Related sensors

LET'S KEEP IN TOUCH

Sign up to receive our newsletters