AXIAL THRUST POSITION MONITORING

Description

Thrust bearing damages can occur within an extremely short time and with little warning.

Monitoring of the axial thrust position allows the early detection of damages and failures of the thrust bearings, which could lead to the destruction of the machine.

The thrust position monitoring is applicable to water turbines, steam turbines and gas turbines.

Typical faults detections

- Wear of roller bearings

- Leakage of hermetic seals

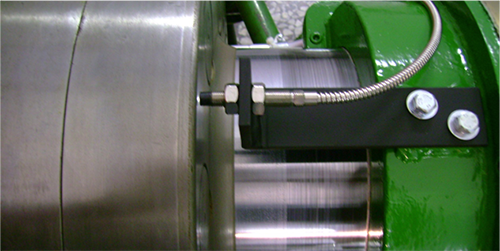

Typical installation

Redundant relative shaft displacement sensors

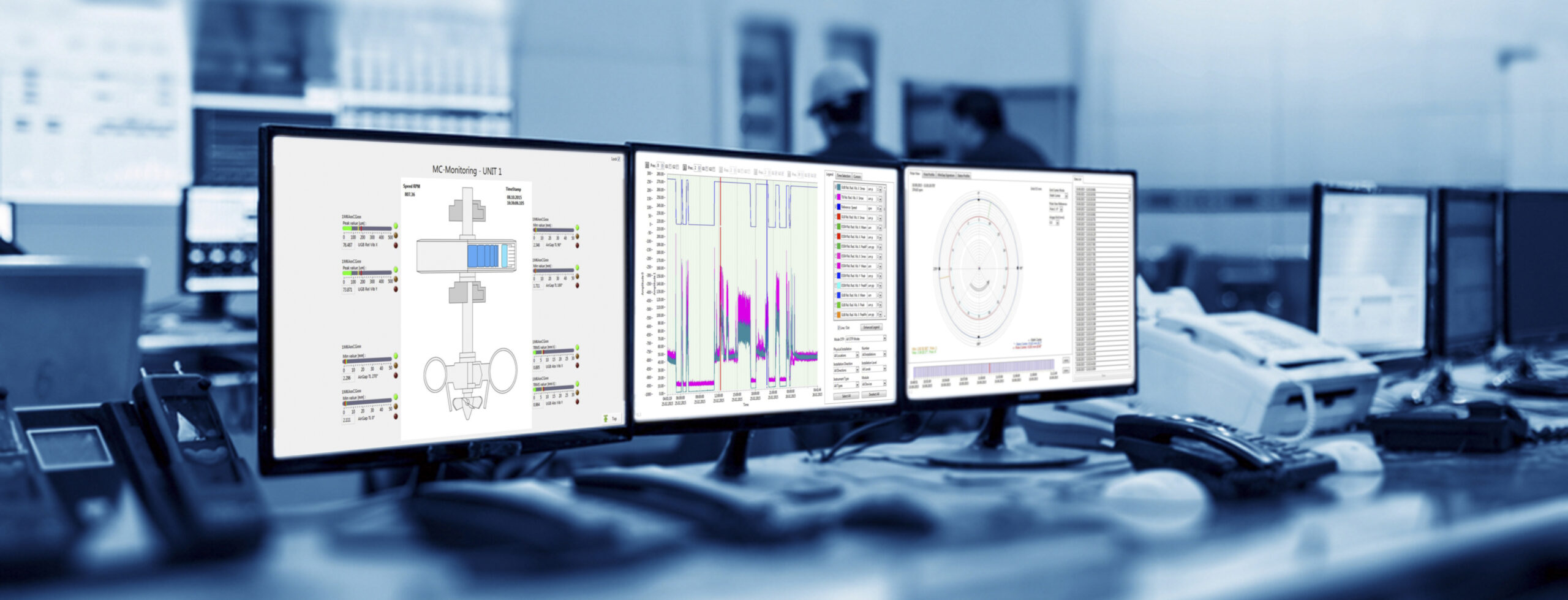

Monitoring parameters

- MPS: Mean displacement deviation

- CMS: Mean displacement deviation

Applications

Related sensors

LET'S KEEP IN TOUCH

Sign up to receive our newsletters