INSULATION AND PARTIAL DISCHARGE MONITORING

Description

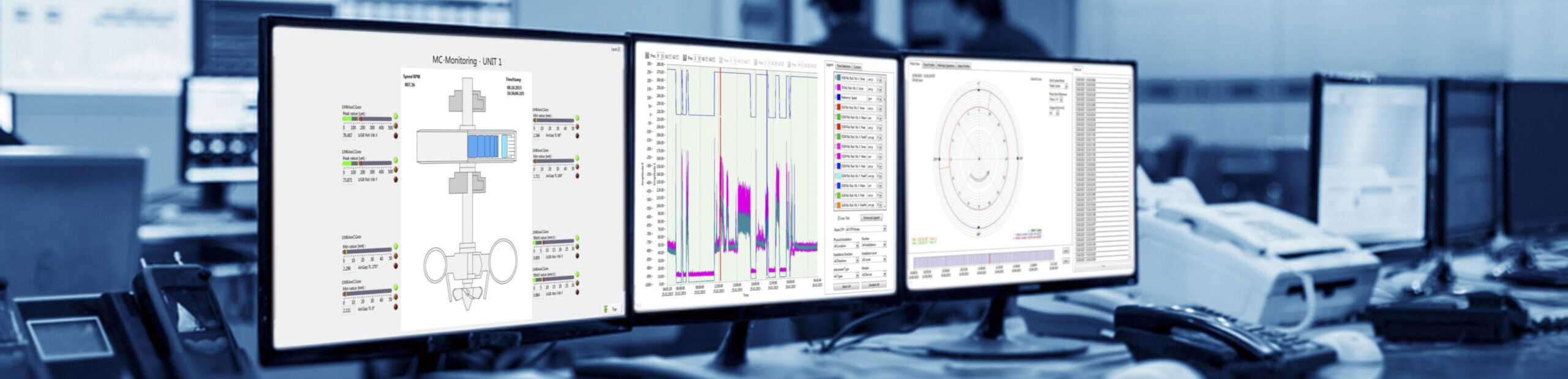

On-line measurements of partial discharges are the only technology available on the market to qualify its stator winding insulation, when a generator or another rotating machine is in service.

The great advantage is that all thermal, electrical, ambient and mechanical forces are present. On-line measurement of partial discharges requires a partial discharge sensor (often called a coupling capacitor) at each phase output.

Once the partial discharge sensors are installed, online measurements can be performed either periodically with a portable partial discharge analyzer or continuously with a permanently installed monitoring system. In addition to the partial discharge signals, this system also acquires operating parameters such as winding temperatures and load conditions to correlate them with the measured partial discharge results.

Typical faults detections

- Delamination of single conductor to main insulation

- Delamination of the main insulation

- Abrasion of the corona slot protection

Typical installation

Partial discharge couplers installed on each generator phase exit.

Monitoring parameters

- MPS: Partial discharge overall activities

- CMS: Partial discharge patterns

Related sensors

LET'S KEEP IN TOUCH

Sign up to receive our newsletters