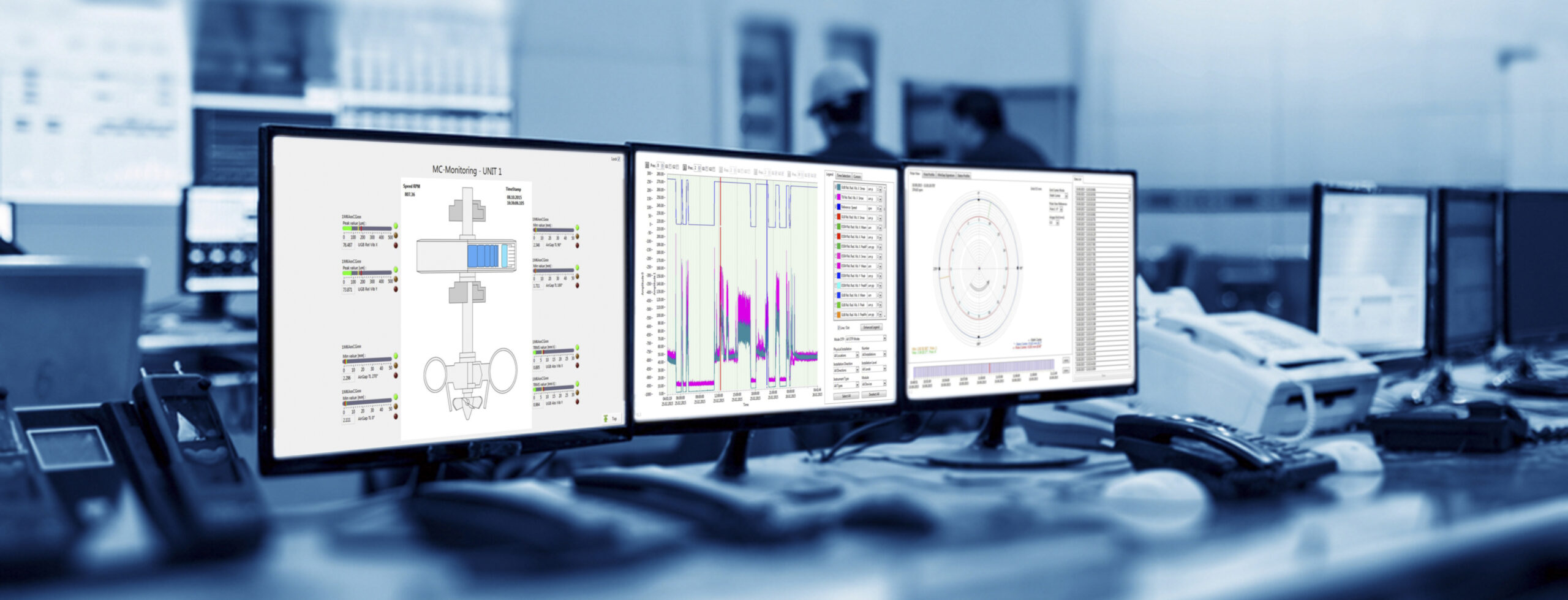

MONITORING SOLUTIONS

Reach the ultimate target of availability and productivity to meet your business objectives for processing plants

The growing demand for productivity and energy efficiency requires constant innovation. MC-monitoring develops highly integrated online monitoring systems combined with robust sensing technologies that meet the requirements of heavy machinery operating in harsh environments.

Our reliable diagnostic system help implement a cost-effective predictive maintenance strategy based on early detection of electrical and mechanical failures in hydroelectric machines, gas and steam turbines, turbo-generators, large industrial engines and gearless milldrives. Potential risks of damage such as stator winding insulation, rotor and stator air gap, and rotor winding temperature are continuously acquired during the operation of the machines, allowing the plant owner to gain insight into the health of the assets and make better decisions.

Rely on our extensive expertise on malfunctions and failure modes affecting critical machines, our advanced monitoring solution, and get a clear decision basis for effectively scheduling predictive maintenance shutdowns!

LET'S KEEP IN TOUCH

Sign up to receive our newsletters