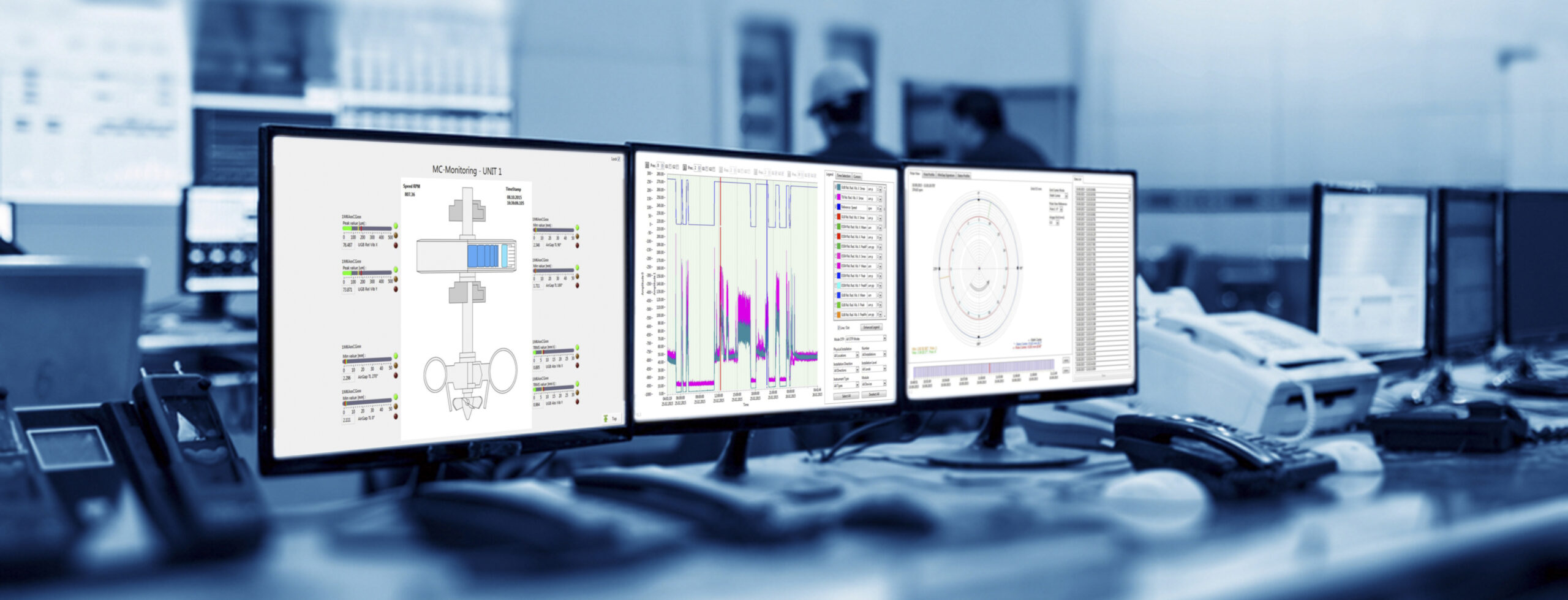

AIR GAP MONITORING

Description

Large, low-speed hydro generators have a very small ratio between the stator bore diameter and the air gap, which makes it impossible to center the elements perfectly during the assembly process. As a result, the machines operate with a small but relevant misalignment.

Faults on the poles can lead to a considerable unbalance of the magnetic attraction forces, which also leads to significant misalignment, vibration, and additional losses.

It is therefore important to assess the following parameters: misalignment; minimum and maximum air gaps; stator and rotor shape; magnetic flux of each pole; and, above all, to check the machine’s mechanical trend, to ensure safe operation and avoid serious damage.

Typical faults detections

- Rotor-to-stator rub

- Pole mechanical instability

- Loss of operating efficiency

- Magnetic unbalance

- Thermal hotspots

Typical installation

Depending on the stator size, between 4 to 16 airgap sensors installed uniformly around the stator core

Monitoring parameters

- MPS: Minimum gap per revolution

- CMS: Pole profile, stator shape, rotor shape, stator and rotor center position, minimum gap position, pole stability

Related sensors

LET'S KEEP IN TOUCH

Sign up to receive our newsletters