CMS-500 SOFTWARE

Key features

- Windows-based client-server architecture:

- Client: data visualization and configuration

- Server: data streaming and recording into SQL database

- PMS-300 Rhino and PMM-300 full integration

- Wide range of graphical data visualization

- Real-time and historical raw data recording and visualization

- Advanced visualization for airgap, magnetic flux, endwinding and runner clearance monitoring

- Cross-correlation database

Description

The CMS-500 Orca Condition Monitoring Software helps to understand the health of your most critical assets and to avoid costly and unplanned downtimes. The system provides a simple view of the condition monitoring data and enables you to make informed decisions to leverage your asset management.

CMS-500 Orca Condition Monitoring Software package consists of a data server and a data client:

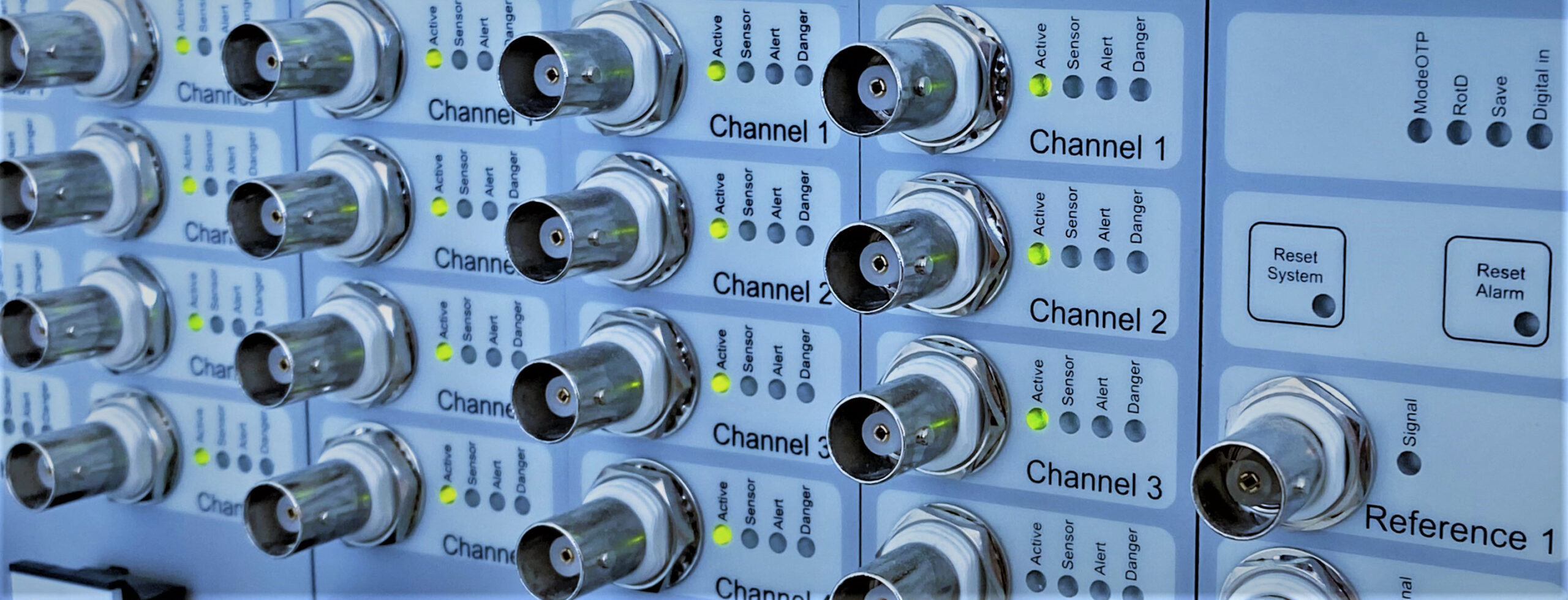

The data server is used to store the data transmitted by the PMS-300 Rhino, MMS-400 Falcon and PMM-300 data acquisition systems in a database. The data server is automatically configured from the connected acquisition modules. The server can store raw data and trends in different tables, allowing efficient data reduction and resolution. In the presence of an event (alarm or danger), the post-trigger raw data is permanently stored in the database. The raw data can also be recorded using timers.

The data client allows you to view the data stored in the database. The client software accesses the database using a TCP/IP protocol. The software provides an effective overview of the health of your plant and machinery by displaying bar graphs and reports. It allows you to track the progress of your machine by viewing trends and perform diagnostics using specific views of the raw data. The diagnostic views available depend on the acquisition mode defined in the PMS-300 Rhino or PMM-300 acquisition modules.

For example, FFT, shaft centerline and orbits are available if the acquisition module is configured for shaft vibration.

The CMS-500 Orca provides a wide range of diagnostic views for monitoring shaft and bearing vibration, air gap, runner clearance, endwinding, stator bar, stator core and magnetic flux. The software allows to cross-reference the data to compare the vibration levels of different start-ups or to correlate the vibration levels according to process parameters (power, speed...).

Monitoring solutions

Downloads

LET'S KEEP IN TOUCH

Sign up to receive our newsletters