Empowering Efficiency: The Game-Changing Impact of Predictive Maintenance Solutions in the Power Generation Industry

Rotating machinery plays a vital role in the power generation industry, and it is crucial to ensure their optimal performance and reliability. At MC-Monitoring, we understand the importance of predictive maintenance solutions for these machines. In this article, we will explore the significance of predictive maintenance and its benefits for the power generation sector.

Early Detection of Faults

Predictive maintenance solutions allow for the early detection of machinery faults, such as imbalance, misalignment, and bearing wear. By identifying these issues in their early stages, maintenance teams can take prompt corrective actions, preventing minor faults from developing into major failures. This proactive approach significantly reduces repair costs and minimizes production losses, ensuring uninterrupted power generation.

Predictive Maintenance

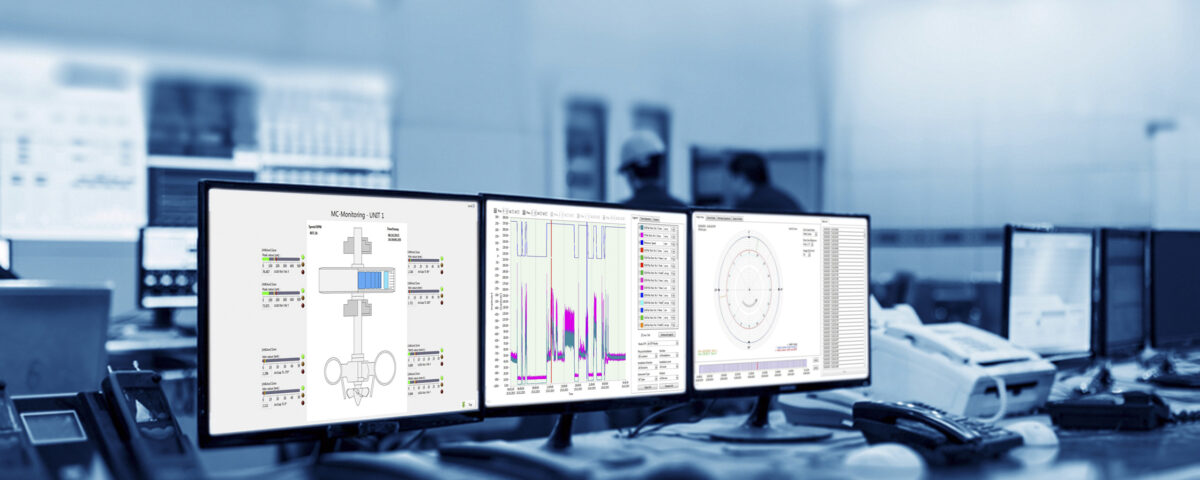

MC-Monitoring offers advanced predictive maintenance solutions that enable organizations to shift from reactive to proactive maintenance strategies. By leveraging our state-of-the-art technology, maintenance teams can analyze machine data and predict when equipment is likely to fail. This enables them to plan maintenance activities in advance, optimize maintenance schedules, extend equipment lifespan, and enhance operational efficiency. With predictive maintenance, unplanned downtime is minimized, leading to improved availability and reliability of power generation systems.

Enhanced Safety

In addition to identifying mechanical issues, predictive maintenance solutions also contribute to ensuring a safe working environment. By monitoring machine performance, including vibrations, organizations can detect potential safety hazards. Excessive vibrations can cause structural damage, compromising the integrity of equipment or surrounding infrastructure. By promptly addressing these issues, MC-Monitoring's solutions enable organizations to maintain a safe working environment, protecting both personnel and assets.

Cost Savings

Investing in predictive maintenance solutions from MC-Monitoring results in substantial cost savings. By implementing proactive maintenance practices, organizations can avoid unexpected breakdowns and costly emergency repairs. This minimizes production losses and optimizes inventory management by scheduling maintenance activities based on actual equipment condition. The result is improved cost-efficiency, better resource allocation, and enhanced financial performance.

MC-Monitoring provides cutting-edge predictive maintenance solutions for rotating machines in the power generation industry. Our comprehensive range of products and services enables early fault detection, facilitates predictive maintenance planning, enhances safety, and delivers significant cost savings.

By embracing the principles of preventive and predictive maintenance, power generation industries can achieve higher levels of operational excellence and stay ahead in today's dynamic business landscape.

Contact us today to learn more about our predictive maintenance solutions and how they can benefit your power generation operations. Let us work together to maximize productivity, reduce downtime, and ensure the reliable performance of your rotating machinery.

LET'S KEEP IN TOUCH

Sign up to receive our newsletters